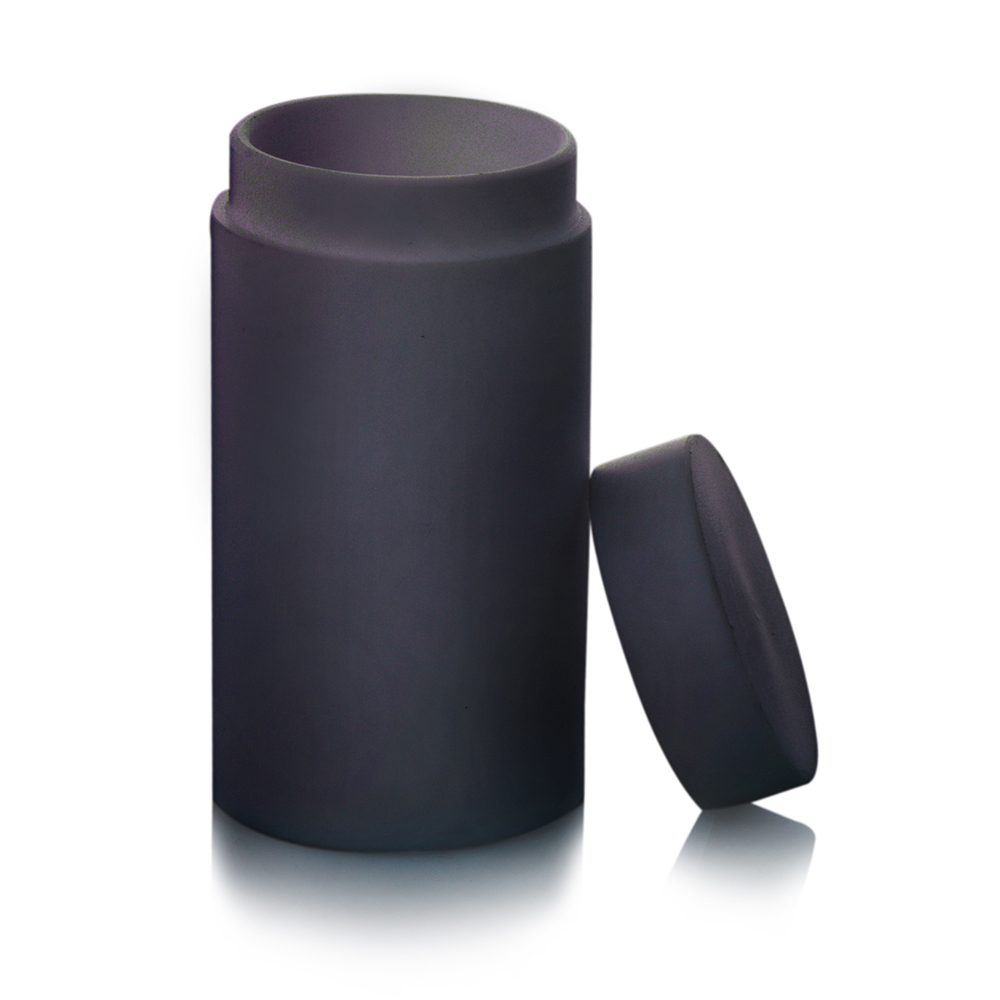

Hydrothermal Autoclave Reactor

Hydrothermal Autoclave Reactor

- Maximum operating temperature: ≤220°C

- Safe temperature: – 200°C

- Working Pressure: ≤3MPa or 30 Bar

- Heating and Cooling Rate: ≤5°C/min

- Material: Shell made of high-quality nonmagnetic 316 stainless steel

- Easy to handle

- Threads are very smooth to lock and unlock

- Can be customized as per requirement

- Primary screw type cap for basic tightening

- Best price and cost effective

- Secondary cap has been provided at the top of the reactor for extra tightening to avoid leakage

- Customized stainless steel jacket/autoclave of SS 316 can also be provided if needed, which is better for corrosive materials.

The Hydrothermal Autoclave Reactor use to carry hydrothermal reaction at high pressure and high temperature. Hydrothermal synthesis reactor generally comes in a two variety; the first is Polytetrafluoroethylene (PTFE) or Teflon lined hydrothermal autoclave reactors and the second is PPL lined autoclave. Hydrothermal reactor mainly made up of two parts; outer high-quality stainless steel jacket and inner Teflon liner or Teflon chamber. In the Teflon-lined autoclave, the reaction is carried out at maximum 240-degree Celsius (428 Fahrenheit), while the safe temperature is 200-degree Celsius (392 Fahrenheit). PPL lined reactor use for the reaction operate at higher temperature, where the safe temperature will be 260-degree Celsius (500 Fahrenheit) and the maximum operating temperature is 280-degree Celsius (536 Fahrenheit). This product extensively used in the scientific laboratory, research and development labs, institutional organizations, quality analysis section in industries etc.

AUTOCLAVE SETUP WITH LINER

| TEFLON LINED HYDROTHERMAL AUTOCLAVE (SAFE TEMP – 200°C) | ||||||

|---|---|---|---|---|---|---|

| Product Code | Description | Reactor Sealing Type | Buy Now | |||

| Teflon Lined Hydrothermal Autoclave (Safe Temp – 200°C) | Teflon Lined Hydrothermal Autoclave | Screw Sealing | BUY NOW | |||

| PPL LINED HYDROTHERMAL AUTOCLAVE (SAFE TEMP – 260°C) | ||||||

|---|---|---|---|---|---|---|

| Product Code | Description | Reactor Sealing Type | Buy Now | |||

| PPL Lined Hydrothermal Autoclave (Safe Temp – 260°C) | PPL Lined Hydrothermal Autoclave | Screw Sealing | BUY NOW | |||

LINER / INNER VESSEL

| TEFLON OR PTFE LINER (HYDROTHERMAL SYNTHESIS INNER CHAMBER) | ||||||

|---|---|---|---|---|---|---|

| Product Code | Description | Safe Operating Temperature | Buy Now | |||

| Teflon or PTFE Liner (Hydrothermal synthesis Inner Chamber) | Teflon or PTFE Liners | 200°C | BUY NOW | |||

| PPL LINER (HYDROTHERMAL SYNTHESIS INNER CHAMBER) | ||||||

|---|---|---|---|---|---|---|

| Product Code | Description | Safe Operating Temperature | Buy Now | |||

| PPL Liner (Hydrothermal synthesis Inner Chamber) | PPL Liners | 260°C | BUY NOW | |||

Full Description of Hydrothermal Autoclave Reactor

Techinstro developed and supply two type of sealing for the tightening of a reactor vessel. The screw type sealing has been given to the reactor with capacity 10ml, 25ml, 50ml, 100ml, 150ml, 200ml, 250ml, 300ml, 400ml, and 500ml, while the flange type sealing will be in a 1000ml, 1500ml, and 2000ml autoclave. We used the double coated Teflon vessel for better performance. The autoclave has been designed to use for external heating where the reactor can be heated in the oven, furnace or self-heating. The ideal heating and cooling temperature rate to get better results will be 5 0C.

The Teflon-lined hydrothermal synthesis autoclave is corrosive resistant. It is also acidic and alkaline resistant hence used for highly alkaline and acidic solutions. The autoclave for hydrothermal synthesis mostly used for crystallization processes and nanoparticles. Since it is operating at a very high temperature and high pressure, hence it is also called as the hydrothermal bomb. Hydrothermal laboratory reactor available with a pressure gauge to maintain appropriate pressure condition required for the chemical reaction. It also comes with features of self-heating with all heating arrangement.

Hydrothermal Autoclave Reactor manufactured by Techinstro are elegantly designed, and are easy to operate; made from high-quality stainless steel structures that guarantee durability, come with gas-tight/air-tight with PTFE inner chamber that reduces corrosion, which is also excellent acid resistance and alkali resistance. Its external heating feature reduces the volume and ensures a favorable reaction in the same reactor operating temperature

The new feature of self-sealing closures is made from durable, reliable cable seal structure, which ensures long-term stability and prevents seeping problem or leakage.

Our aim has been to offer our customers top quality high-pressure Hydrothermal Autoclave Reactor, customized for each application and technically supported by highly competent and skilled staff. Contact us with specifications, and we shall help you to configure a system that will suit your requirement and make one for you!

Techinstro offers high-pressure standard capacities Hydrothermal Autoclave Reactor. We also customized as per your application. Write to us with your specifications or get in touch to enable us to help you find the perfect configuration.

At Techinstro, customers can select from a wide range of non-stirred pressure vessels; available in different styles, sizes, and pressure ranges for a variety of uses in laboratories.

APPLICATIONS AREA

- Environmental science

- Energy

- Advance material science

- Material Engineering

- Nanotechnology

- Polymer industry

- Catalysis

- Petrochemical Industry

PRECAUTIONS

- Heating rate: 5 0C per minute

- Cooling rate: 5 0C per minute

- Heat resistant gloves must be used while handling

- Proper tightening of primary as well as secondary cap to avoid pressure leakage

APPLICATIONS

- Chemical synthesis

- Synthesizing of nanoparticles

- For cultured crystal growth

- Polymerization reaction

- Hydrothermal decomposition

- Catalyst synthesis

- Hydrothermal oxidation

- Hydrothermal precipitation

- Material Digester / digestion

- Crystallization process

- Dissolve of heavy metals, refractory material, organic chemicals etc.

OPERATING GUIDE

1.Place the Autoclave and sterilizing material on the table or on the shelf.

2.Twist the screw type threaded primary SS cap (SS Alloy 304) in an anticlockwise direction until it has been opened.

3.There is 2 type of SS gasket/lid in the reactor, 1 is on the bottom side and another is on top of the Teflon vessel chamber.

4.Lift the top SS gasket or lid and take-out milky white colorPTFE/Teflon reaction chamber.

5.Now fill solvent (as per liner’s capacity) in the reaction chamber and sealed it.

6.Make sure that the Teflon cap should be air-tight to avoid pressure leakage.

7.Place Teflon or PTFE liner in a stainless steel chamber.

8.Keep top gasket over the vessel and make sure that the Teflon-lined vessel placed properly inthe Stainless Steel chamber.

9.Then twist primary SS cap in a clockwise direction until it does not turn anymore.

10.The secondary SS cap has been given at the top of the primary cap for extra tightening to avoid pressure leakages.

11.Rotate primarySS cap in the clockwise direction with the help of locking rod for additional tightening.

12.Placed the hydrothermal autoclave in oven or furnace and heat it till reactor’s safe temperature.

13.Increase the temperature of the oven and set heating rate5 0C/minute only.

14.A researcher can heat the hydrothermal autoclave till 200 0C for safe use.

15.After completion of the hydrothermal synthesis reaction, the autoclave’s cooling rate will be 5 0C/minute.

16.Make sure that, after completion of the process clean PTFEor Teflonliner properly for reuse.