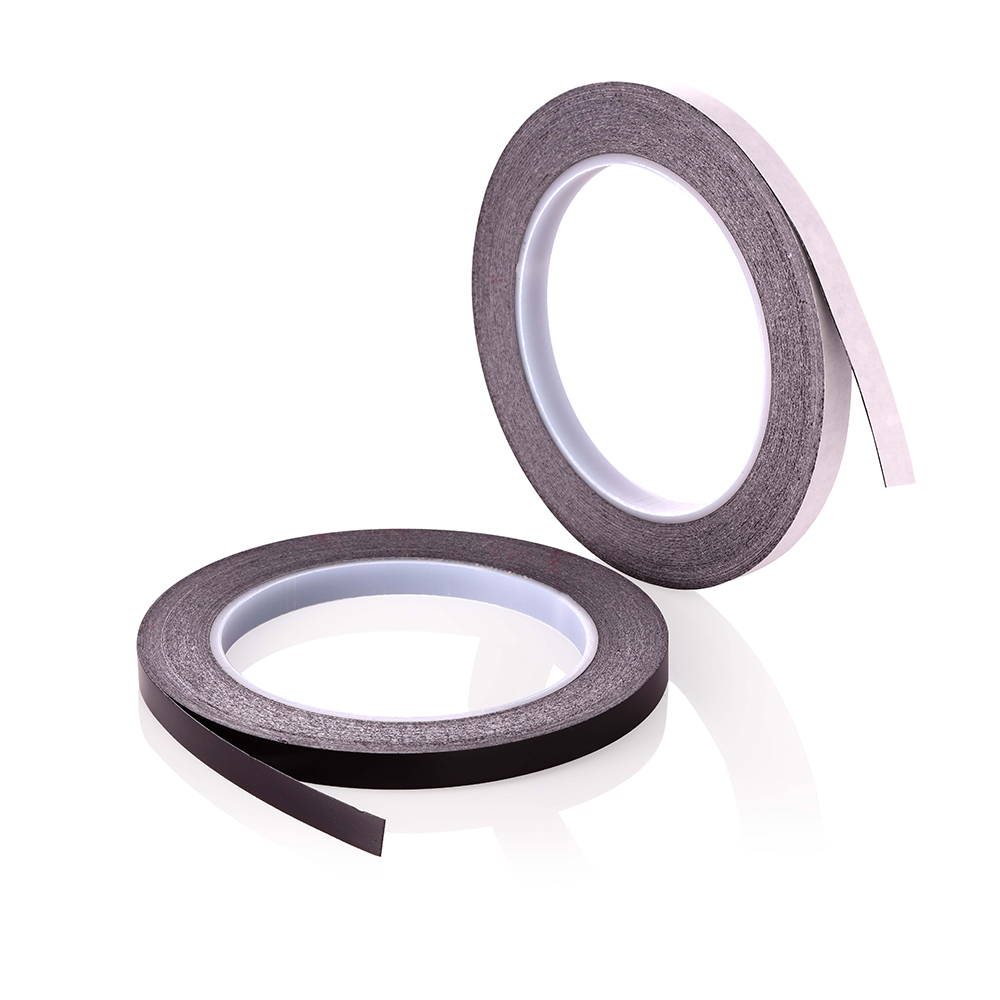

Carbon Tape

Carbon Tape

- Width – 8mm

- Length – 20m

- Tape thickness – 160micron

- Plastic Core Diameter – 76mm

- Adhesive thickness – 15micron

- Operating temperature range – 120 degrees C

- Resistance – 5 Ohms/sq

These are some of the premium properties that make carbon conductive tape such an excellent solution for SEM/EDS applications.

A carbon tape is a perfect solution for joining two components together firmly and ensuring optimal conductivity between them. Hence it is also known as a carbon conductive tape. The quality and construction of the conductive tape need to be high to ensure reliability in applications.

It is a non-porous and conductive adhesive strip which is best-suited for EDX and SEM applications. These tapes are available with single-sided or double-sided carbon conductive tape.

Full Description of Carbon Tape

In simple words, it is designed to install electrical conductivity between two hard surfaces which also need to join together. As these strips do not use liquid or colloidal adhesive solutions, it becomes safer and more comfortable to mount samples quickly.

The carbon tape is made using the best quality material for the tape itself, which has only trace amounts of Silicon and Aluminum. This material made from the non-woven liner and coated on one or both sides with a non-liquid, conductive adhesive solution. The adhesive itself is carbon-filled acrylic and highly sensitive to pressure, which makes it perfect for adhesion to several materials, including small fiber particles, paper, glass, wood, rubber, wafers, ceramic, plastics, and metals.

The carbon tapes are impurity free and completely transparent. Although the conductivity of single-sided carbon conductive tape is noticeably lower than the double-sided carbon conductive tape both of these are suitable for use in EDS or SEM applications.

Carbon Tape Applications

These are some of the principal uses of high-quality carbon tape in industries and R&D labs across the world:

- Repairing defective conductor on printed circuit boards

- Fixing glitch rear windscreen heater

- Alternative to soldering, if heat can damage electrical component

- Making ‘Faraday Cage’ to protect sensitive electrical instruments from electromagnetic radiation

- SEM (scanning electron microscopy) applications to prevent electrostatic charge developing in the surface

Why Techinstro?

At Techinstro, we ensure that each customer can order customized, cost-effective carbon conductive tape, with varying width and properties, which makes them suitable for all types of industrial and R&D applications.