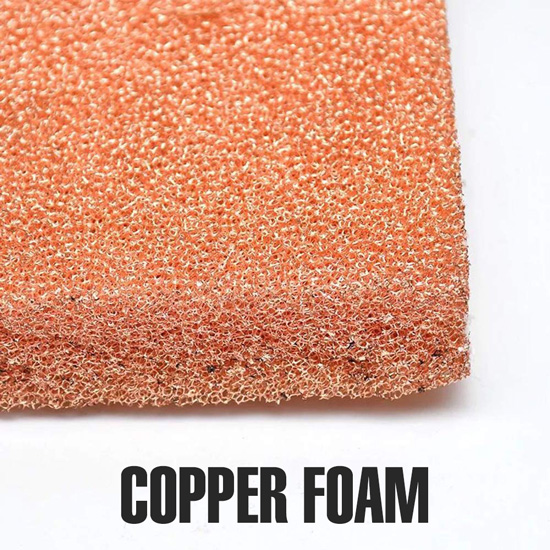

Copper Foam

Copper Foam

• Damping materials

• High-efficiency thermal conductivity materials

• Industrial filtration materials

• High-grade aesthetic materials

Copper Foam Specification and Details

Copper foam (Cu foam) is a crystalline solid skeleton structure with a robust, extremely porous, permeable structure and a regulated foam density per unit volume. The cell and connective matrix are reproducible, regular, and consistent throughout the material. It is not crushed, coated, or plated in any way. Its purity is generally the same as that of the original alloy copper, with no holes, impurities, or impalements. Copper metal foam performs admirably in heat transfer applications. Copper Foam Sheet has been extensively applied in fabricating battery negative carrier materials, electrode substrates of lithium-ion batteries or fuels, cell-catalyst carriers, and electrical insulation materials. It is the foundation of a battery electrode, and it has several significant advantages.

Micro-porous copper foam has the appearance of an open-cell structure, with an unusually high number of interconnecting pores spread evenly throughout the underlying copper substance. It has good thermal characteristics and may be widely employed in heat conduction radiation motor/electrical and electronic components. The industry is also interested in copper metal foams due to their excellent electrical conductivity, nickel-zinc battery, and use of polymer electrolytes for an electric double-layer capacitor. Filtering elements of Cu foam are superior water purification filter materials due to their foam structure properties and are non-toxic to the human body.

Copper metal foam structures with open porosity walls have been successfully sculpted utilizing an electrochemical deposition process gas. The foams pore diameters and wall architectures may change by altering the deposition conditions. The fall in pore size is due to the addition of a bubble stabilizer (e.g., acetic acid) that reduces bubble convergence. In contrast, the reduction in branches in the foam wall is due to the electrocatalytic activity of chloride ions in the metal deposition process.

In addition, the response surface approach helps investigate the impacts of carbonate volume percentage and pore volume on the flexural behaviour of mechanically optimized foams. Based on the examination of variances, it was discovered that decreasing porosity improves the mechanical characteristics of the foams while reducing average pore sizes has a comparable effect. Porous metallic materials, also known as metal foams, have gained popularity due to their unique qualities such as high specific strength, heat resistance, and electrical conductivity. Based on their openings and connectedness, pore size distribution in metal foams may be open and closed pores. Metal foams with open interconnecting pores are multifunctional, particularly in heat and mass transfer applications.

Properties of Copper Foam

Thermal Conductivity

For its size and weight, the product has high heat conductivity. Heat transmission to/from fluids moving through the foam is substantially increased compared to solid fins because of the increased surface area. Because of the enormous surface area is also suited for usage with phase change materials (PCM), which enhances coupling to PCM.

Pressure Tolerance

When anyone pressures the metal foam sheet structure, it initially yields elastically. However, due to the sample size, the structure begins to bend and constantly collapses at a pretty constant tension at around 4-6% of strain. This continual collapse will progress to approximately 50-70% of strain depending on the initial volume concentration of the foam. As the compressed foam reaches the “compaction” phase, the stress/strain curve will climb. The pressure tolerance of the foam is the point on the stress/strain curve when it switches from the elastic to plastic deformation phase. That is a crucial engineering parameter since it is necessary for any structure that keeps its form under design load to operate below that level.

Conductivity of electricity

Copper is an excellent conductor. As a result, researchers can use the foam as a conducting medium or as an electrode in dielectrics. It’s also shielded against electromagnetic radiation. It is because of the foam’s massive surface area.

Density

We create this product from solid copper that has a low density. The resultant foam is extraordinarily light and popular in weight-sensitive aeronautical applications. We can lower the relative density of the foam to 3% to 12%. Post-foaming compression is excellent for generating higher densities. It has a max tensile ratio as well. It’s a perfect choice for lightweight construction applications. It is an appropriate medium for goods such as aviation air oil separators due to its high surface area/volume and improved tortuosity, which may be modified to provide optimal pressure drop.

Coatings

The copper sheet foam may be anodized, chemically coated, and metal-plated in the same way as solid copper can for better corrosion resistance and heat conductivity.

Corrosion Resistance

This layer is generally stable at pH levels ranging from 4.5 to 8.5. Copper is exceptionally corrosion-resistant within that pH range. Copper innately has a strong oxide coating that helps resist corrosion.

Applications of Copper Foam

Catalyst and carrier filter medium and medium in the separator are examples of chemical engineering fields where Cu foam finds its application. Moreover, in industrial and thermal engineering, its uses are

• damping materials,

• high-efficiency thermal conductivity materials,

• industrial filtration materials, and

• high-grade aesthetic materials.

As a Buffering material, it is efficient as a pressure-reducing device used in pressure gauges. It is helpful in Silencer, vibration absorption, buffer electromagnetic shielding, stealth technology, flame retardant, thermal insulation, and other functional materials. Furthermore, it is popular in producing battery electrode frame materials such as nickel-zinc batteries, nickel-hydrogen batteries, and electric double-layer capacitors. Vehicles lighter in weight, ships lighter in weight, and structures lighter in weight are all examples of lightweight due to the copper metal foam.

How To Use Copper Foam?

• Take out the product from the container and place it on a clean surface.

• Make sure you’re wearing your safety equipment.

• Use the product under the experiment’s specifications.

Safety Measures?

• Because the copper metal foam sheets may have sharp edges, Heavy Duty Gloves are mandatory.

• Dress in a full-sleeved shirt, long pants, and shoes to avoid direct contact with the metal.

• If the research includes chemical gas exposure, wear protective glasses and masks.

• Keep fire extinguishers available to avert mishaps.

Why Choose Us?

Techinstro commits to providing exceptional quality goods to our clients. We are a known manufacturer of copper foams and various other metal foams. We have a dedicated staff with over ten years of industry expertise. As a result, we understand our clients’ requirements and can meet them. The products are of high quality and fit the needs of both industrial and research applications. We provide product customization based on our clients’ needs, where our professionals serve clients with product assistance 24 hours a day, seven days a week. You will be delighted if you work with us. Our items may be shipped anywhere in the world. Contact us right away to place your purchases.